In migrating all this material from the Google Photos album to here, I noticed that I’ve made reference to items, or promised follow-up, that I haven’t actually gotten around to sharing yet. So let’s catch us up on some things!

First, I thought some of you might enjoy seeing exactly what my pile of rough turned bowls looks like. At the moment, it isn’t a single pile. I’m in the process of moving my storage area from the loft of the shop to the loft of the shed. The plan is that the shed will become my dedicated workspace. It’s a nice sized space, with a tall ceiling and three big windows. I’m looking forward to it! And then there are a few bowls waiting to be finish turned, currently stashed under my lathe. And about a dozen (no photo) tucked away in shavings for initial drying.

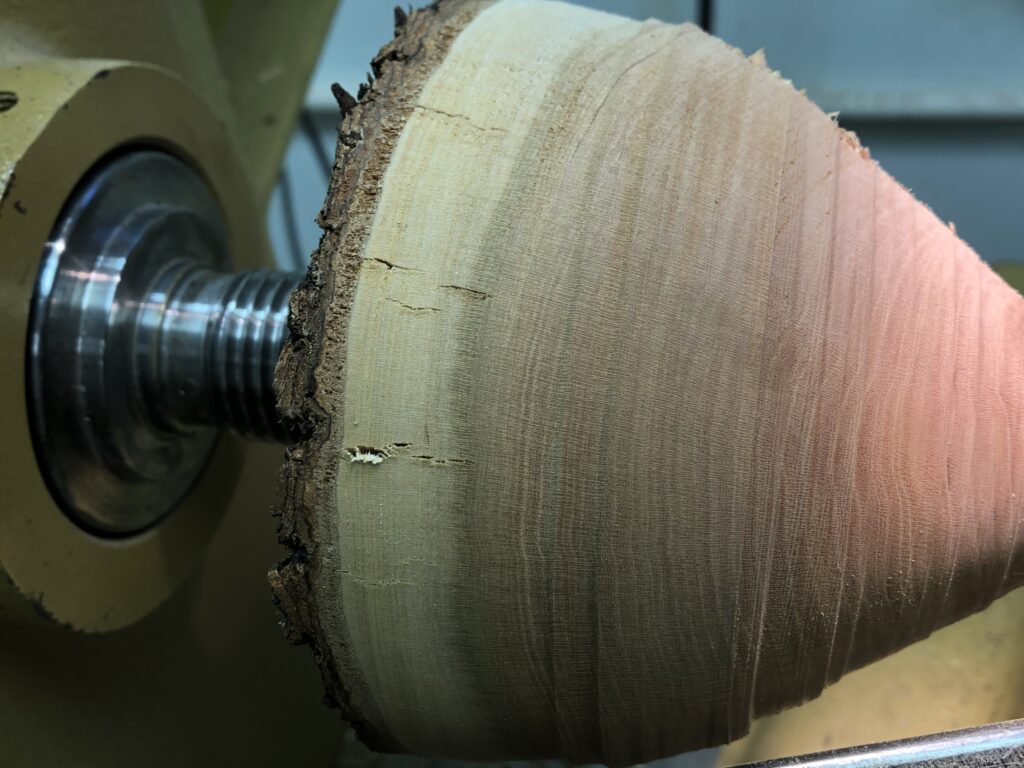

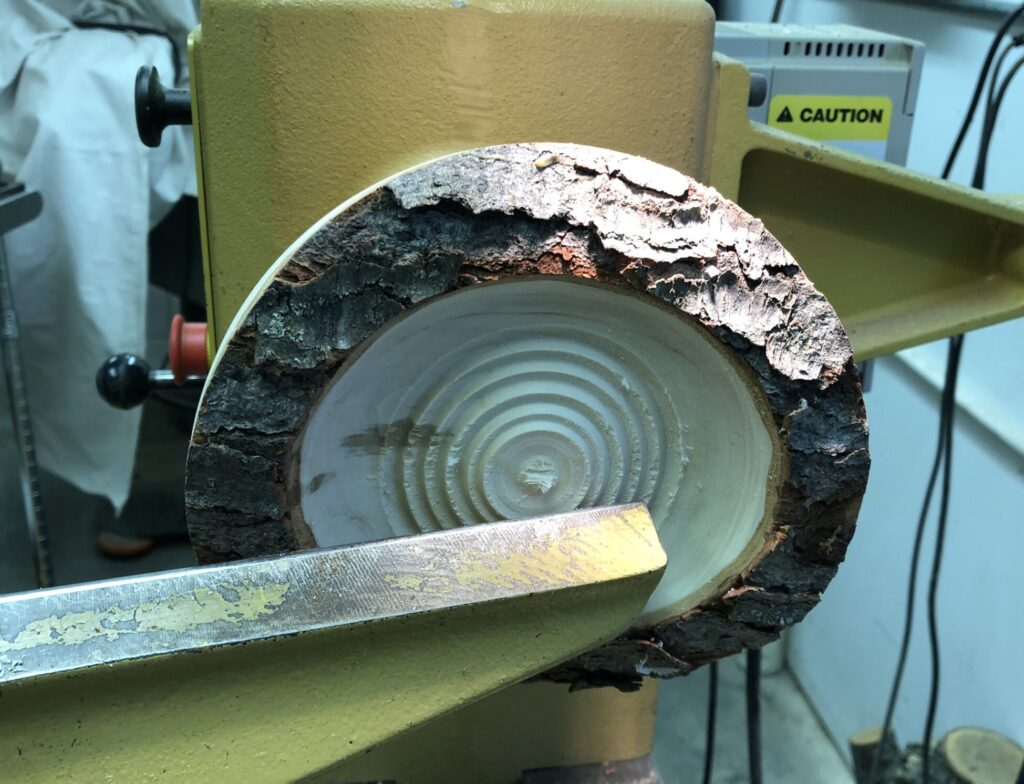

I think I promised a photo of the natural edge butternut once it had finish applied. Here it is, along with a black walnut natural edge that I was pretty happy with.

Then, I thought I’d share some photos of some of the other completed items I’ve accumulated (and not yet parted with).

Here is a collection of oak bowls

and some beech bowls. On a couple of them, I tried my hand at dyeing the outside (blue and an olive green)

Spalted maple

and, finally, some silver maple. This is the same wood that split terribly on two big bowls (“I’m still at it” in March). These didn’t split… and they dried amazingly fast. So I’m still not sure what’s up with that wood. But these came out ok.

Not photographed are the quick, fun items I’ve been turning in between using up scraps–things like wine stoppers, square plates, vases, more ornaments. Maybe next time!