I’m not kidding! A friend took it as a challenge to find me some species that I hadn’t yet turned. He showed up with 14 logs, twelve different varieties: cherry, poplar, hard maple, soft maple, red oak, white oak, cedar, elm, butternut, ash, apple, and… American chestnut. I think he wins the “find something special” award.

The chestnut has actually been laying around for awhile, so I figured I might as well start there. And really, who wouldn’t? So, after checking in with another turning friend for any clues he might offer on handling the chestnut, I dove in.

Isn’t that gorgeous coloring? The middle piece is the thin slab I usually take out of the middle of a log and set aside for small plates or spindles. the two large chunks moved along the process to becoming bowls. The first step is marking out the bowls, where I notice the first crack. Here is my layout for one half of the log. I split it across to get one medium bowl (right), and one small bowl and two small spindles worked around the crack (left).

So, I worked around that crack on the left. I’ll get a couple chunks just the right size for two very nice whiskey stoppers. (I’m not sure why, but I think this wood goes better with whiskey.). And I’ll still get a small bowl from the right side. And a medium sized bowl from the piece on the right. The medium bowl did show a bit of cracking. I was hoping I could turn the medium bowl shallow to get below the X’ed out crack. Step two is further breaking down and trimming on the bandsaw, then drill center holes for mounting on lathe.

Definitely wasn’t going to get that second small bowl. That piece split completely on the crack when I bandsawed between the two small bowls. What didn’t really dawn on me until later, was that crack wasn’t just a crack–it was actually a separated ring… that probably didn’t happen to stop separating at the point I cut the log half in half again …. I bet you can see where I’m going, here. When I drilled the small bowl for mounting, it too split just like the piece on the right (photo further below).

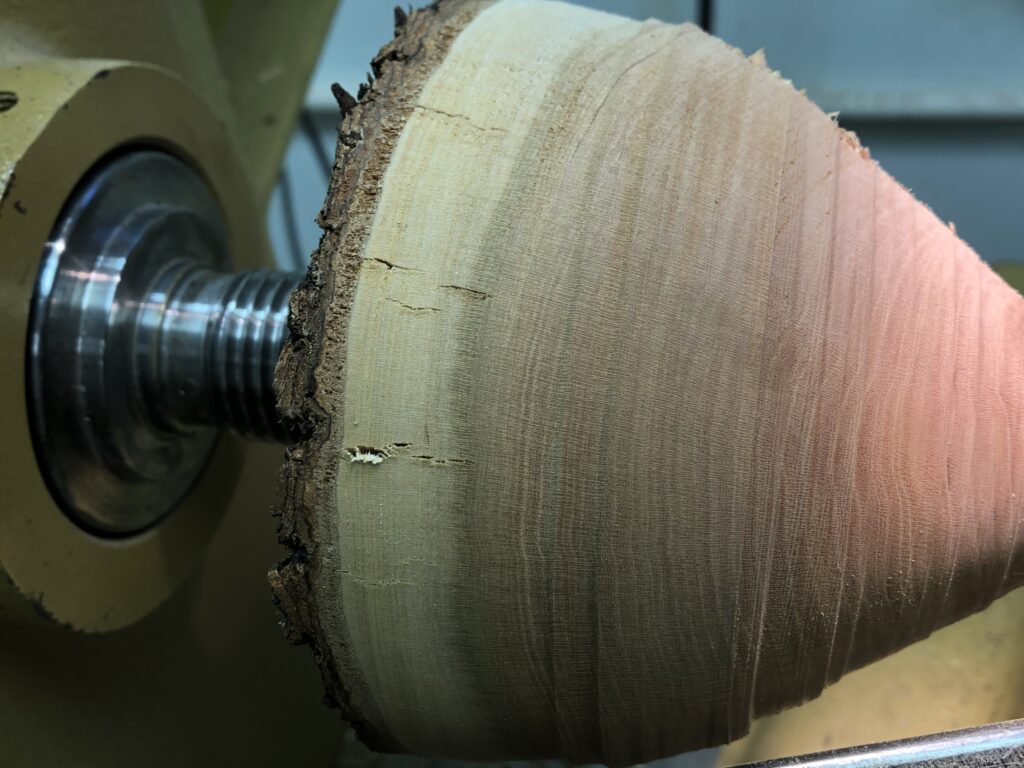

So let’s put the medium bowl on the lathe. There were also longitudinal cracks in the log that I knew about. I knew I was going to have to cut deep enough into the log to get beneath them.

I kept cutting, and got to a beautiful clean surface. No more longitudinal cracks, but now I have a crack on each side that followed the separated growth ring.

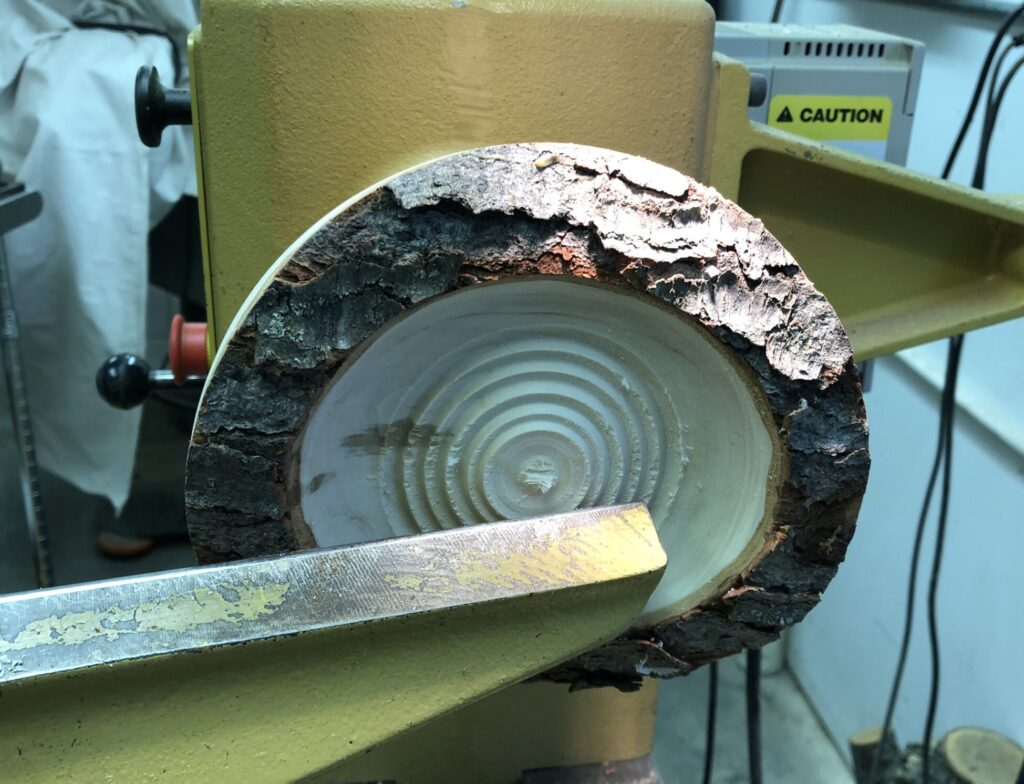

I tried gluing them up, but when I flipped the bowl to hollow out the inside, another crack appeared, and kept opening. I know some turners deal with cracks as a feature, but I’m still a bit timid about having the bowl blow apart and across the room. So I stopped hollowing about 3/4″ down.

I still had a single big bowl planned for the other log half. Miraculously, that did hold together. What with the longitudinal cracks, it ended up being smaller than I had hoped. But it seems pretty solid, and even if it’s smaller than planned, it’s very pretty. And unusual.

So all I have to show for several hours of work are two blanks for whiskey stoppers (not in photo), a split apart small bowl and an almost split apart medium bowl that I’m not sure yet what to do with, and one now-medium sized bowl. I’m a bit bummed, but also still excited to hopefully have the one bowl survive the drying.

And 12 wood types + 14 logs … must have been some repeats, right?. Yup, two cherry and two chestnut. The other chestnut is a bit bigger than this one. So I get to have this whole adventure again. But now I know to look closely at that growth ring. If it looks bad, I won’t even try for bowls. I’ll cut up for spindles to be used for boxes or peppermills or such.